Powering today’s industries with tomorrow’s fuels.

Circularity Fuels™ makes sustainable aviation fuel by combining biogas and clean energy.

Technology that stands out.

Circularity Fuels™ is the global leader in biogas conversion to sustainable aviation fuels.

CCC Catalyst™️

Circularity Fuels’ proprietary Triple C Catalyst™️ combines the power of sorbents and catalysts to convert complex streams like biogas into syngas that is perfectly suited for conversion into liquid fuels like sustainable aviation fuel.

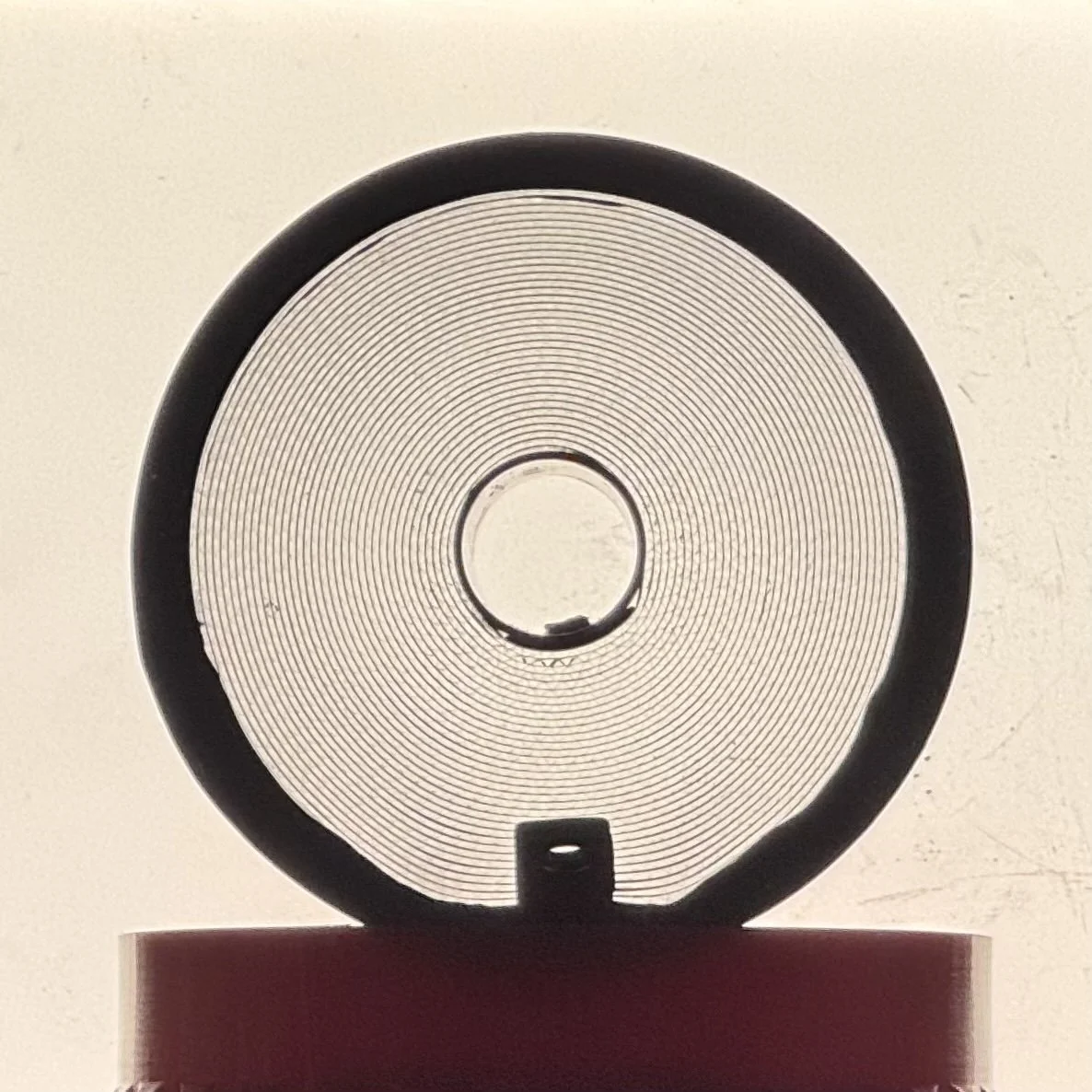

Radically Affordable Ouro Reactor™️

The Ouro Reactor™️ is a fully electrified microchannel reactor that is 100x cheaper than gas-fired reformers. Our proprietary reactor combines the benefits of automotive catalytic converters (affordable, mass manufacturable, compact, low pressure drop) with the benefits of a joule-heated reactor (high efficiency, high temperature, capable of dynamic operations). With thousands of hours of operation at temperatures near 1000 degrees Celsius, the Ouro Reactor™️ is the most affordable, most compact electrified solution for converting methane and carbon dioxide into syngas.

The Ouro Reactor™️ is named after the ancient Egyptian symbol for circularity—the Ouroboros. Much like the snake eating its own tail, our novel reactor architecture allows carbon to be endlessly recycled into fuels.

Reactors Sized for the Resource

Circularity Fuels unleashes unprecedented economics for biogas resources as small as 100 standard cubic feet per minute. Our reformer, capable of producing syngas for a 2-barrel-per-day sustainable aviation fuel plant, is only slightly larger than a coffee mug, enabling truly modular off-site construction of gas-to-liquid plants that are easily installed at biogas resources.

Making Next-Generation Fuels a Reality

Circularity Fuels’ biogas-derived SAF qualifies as both non-HEFA and PtL SAF under the UK’s SAF mandate and RFNBO under the ReFuelEU Aviation mandate. By making affordable second and third generation sustainable aviation fuel, we help airlines meet their regulated SAF offtake at an affordable price.